If you’ve ever spent too long hunting for a product in your warehouse or realized too late that you’re out of stock, you know how quickly inventory chaos can disrupt your day.

A sound spreadsheet system makes it easier to see what you have, where it’s stored, and when it’s time to reorder.

Our free warehouse inventory template gives you a straightforward way to organize your stock information in one place.

The template is available in Google Sheets, Excel, and PDF formats, allowing you to get started with the tools you already use. Download it and get your inventory sorted without the hassle of learning new software.

Quick Jump

ToggleWhat Is a Warehouse Inventory Spreadsheet?

A warehouse inventory spreadsheet is a simple digital tool that businesses use to track the products they have in stock, their location, and the movement of inventory in and out of the warehouse.

It helps managers stay on top of their inventory, allowing them to avoid running out of popular items or ending up with too much of something that isn’t selling.

Download Spreadsheet Daddy’s Free Warehouse Inventory Management Spreadsheet

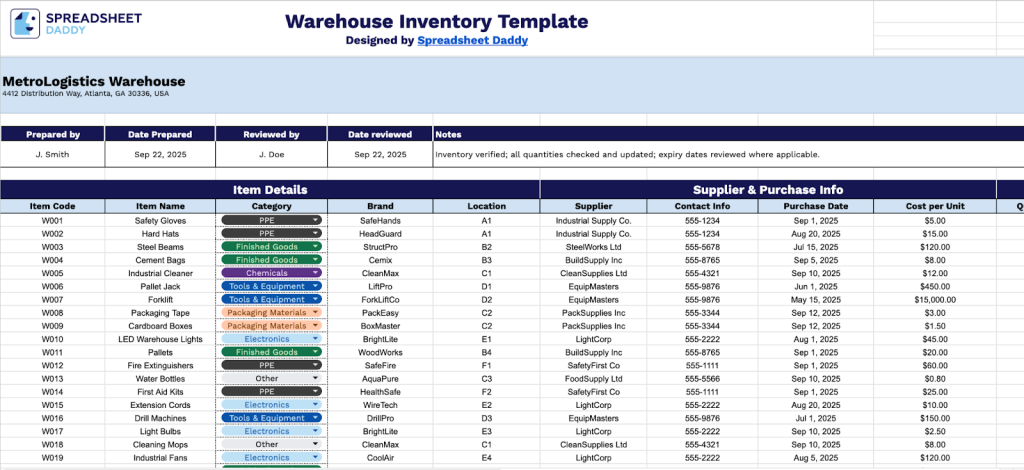

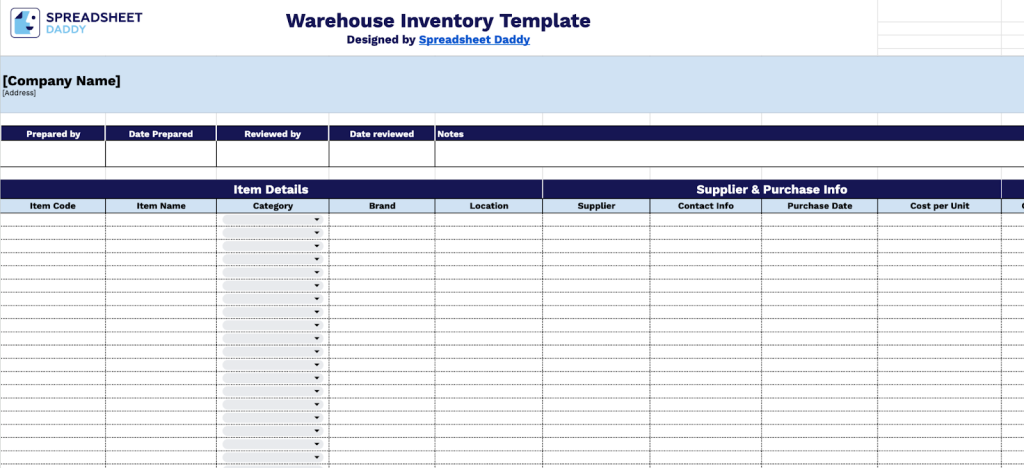

Our comprehensive warehouse inventory template provides a professional framework for tracking and managing your stock across multiple locations.

Designed to streamline inventory operations, it includes essential tracking fields organized into logical sections covering item details, supplier information, quantity management, and inventory movement.

The template is fully customizable, enabling you to modify the columns to match your unique operational requirements and business processes.

What’s included

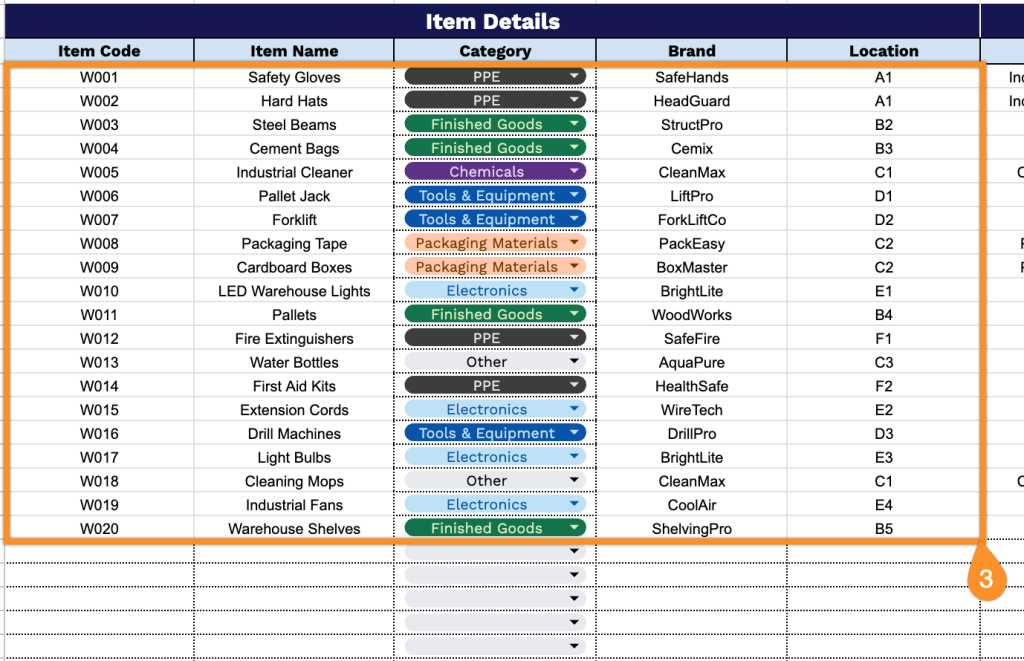

- Comprehensive item tracking system: Keep tabs on every product in your warehouse with fields for Item Code, Item Name, Category, Brand, and Location. Find what you need quickly and know exactly where everything is stored.

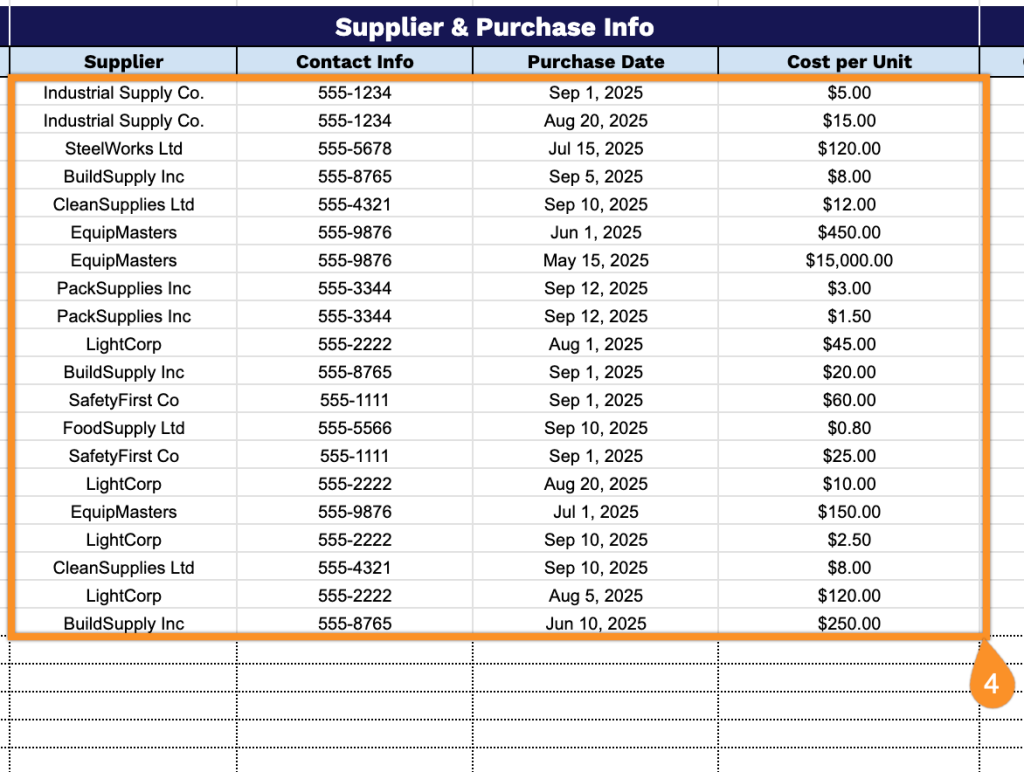

- Supplier and purchase management: Store all your supplier details in one place, including contact info, purchase dates, and costs per unit. Makes reordering straightforward and helps you maintain strong relationships with your vendors.

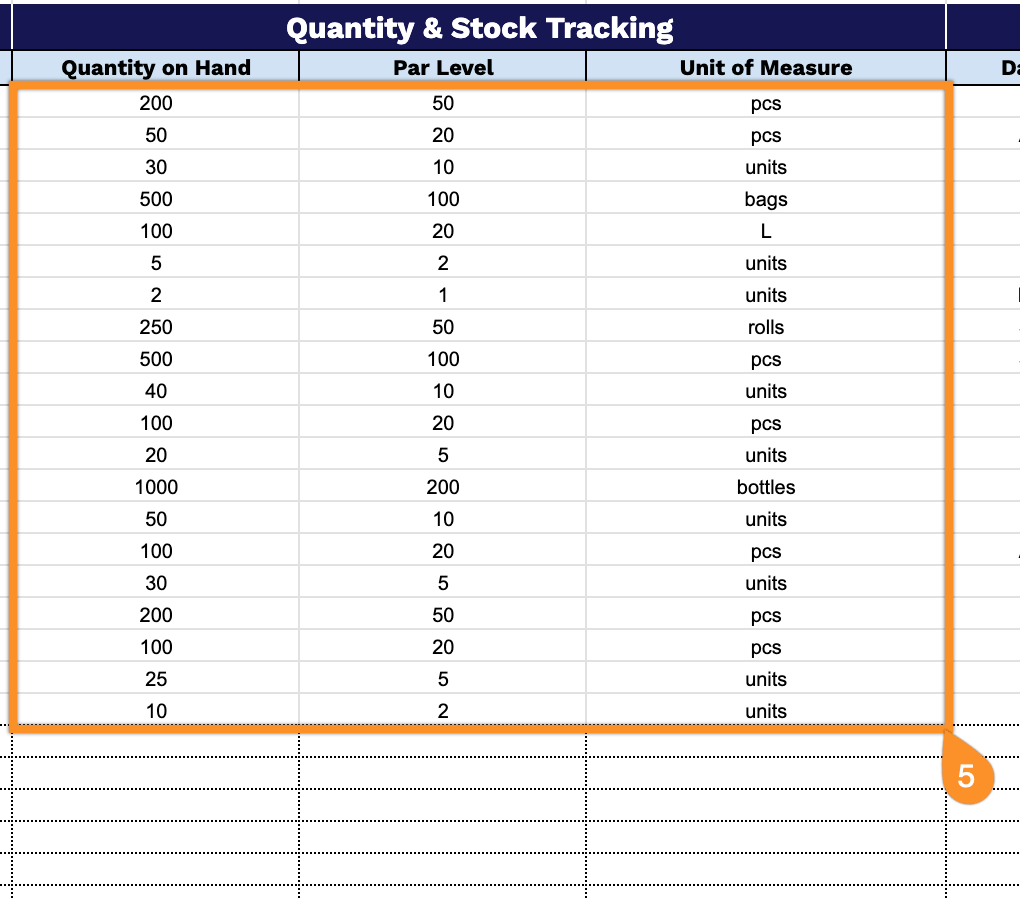

- Real-time stock level monitoring: Stay on top of your inventory with Quantity on Hand, Par Level alerts, Unit of Measure, receiving dates, and expiration tracking. The template automatically calculates days remaining so you can avoid running out of stock or dealing with expired items.

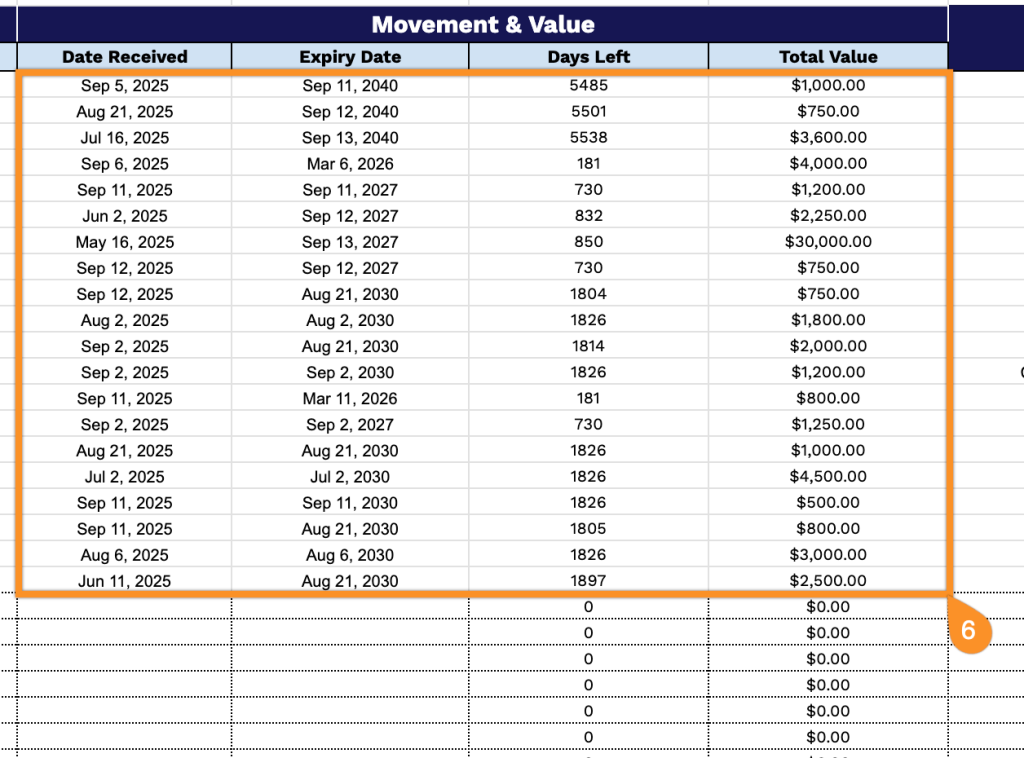

- Automated financial calculations: The template multiplies your Cost per Unit by Quantity on Hand to give you instant visibility into what your inventory is actually worth, with no manual calculations needed.

- Scalable template structure: Comes ready with 60+ rows for your inventory items, organized into clear sections (Item Details, Supplier & Purchase Info, Quantity & Stock Tracking, Movement & Value). Easy to customize and expand as your warehouse grows, with built-in fields for who prepared and reviewed the inventory, dates, and notes.

How to Use Our Warehouse Inventory Spreadsheet Template

1. Implement this template by making your own Google Sheets duplicate or exporting it to Excel or PDF.

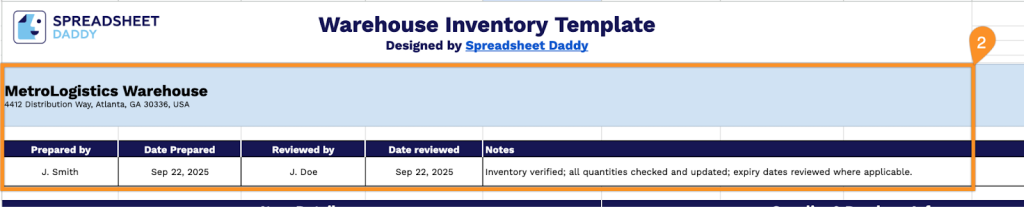

2. Document your business name, physical address, and stock coordinator information together with the finalization date, then specify the manager’s name and inspection date while applying Notes for any additional details.

3. Complete the Item Details section by entering all essential warehouse inventory information:

- Item Code: Enter the unique identifier or SKU assigned to each product for inventory tracking and organization.

- Item Name: Specify the complete product name and description of the item being stored.

- Category: Select the appropriate classification for the item (Raw Materials, Finished Goods, Equipment, Spare Parts, etc.).

- Brand: Include the manufacturer or brand name associated with the product.

- Location: Record the specific warehouse location, aisle, bin, or zone where the item is stored for efficient retrieval.

4. Document supplier relationships in the Supplier & Purchase Info section for vendor management:

- Supplier: Enter the name of the vendor or manufacturer providing the inventory items.

- Contact Info: Include phone numbers, email addresses, and key contact persons for ordering and support.

- Purchase Date: Record the date when the items were acquired from the supplier.

- Cost per Unit: Enter the purchase price paid to acquire each unit for cost tracking and financial analysis.

5. Track stock levels and inventory control data in the Quantity & Stock Tracking section:

- Quantity on Hand: Document the current number of units physically available in the warehouse.

- Par Level: Set the minimum stock threshold that triggers reordering to prevent stockouts.

- Unit of Measure: Specify how items are counted or measured (pieces, boxes, pallets, liters, etc.).

6. Monitor inventory movement and valuation in the Movement & Value section for operational efficiency:

- Date Received: Record when items were delivered and entered into the warehouse inventory.

- Expiry Date: Document the expiration or best-before date for perishable or time-sensitive items.

- Days Left: The template automatically calculates the remaining shelf life before expiration to prioritize stock rotation.

- Total Value: The template automatically computes the total monetary value of inventory on hand for asset tracking.

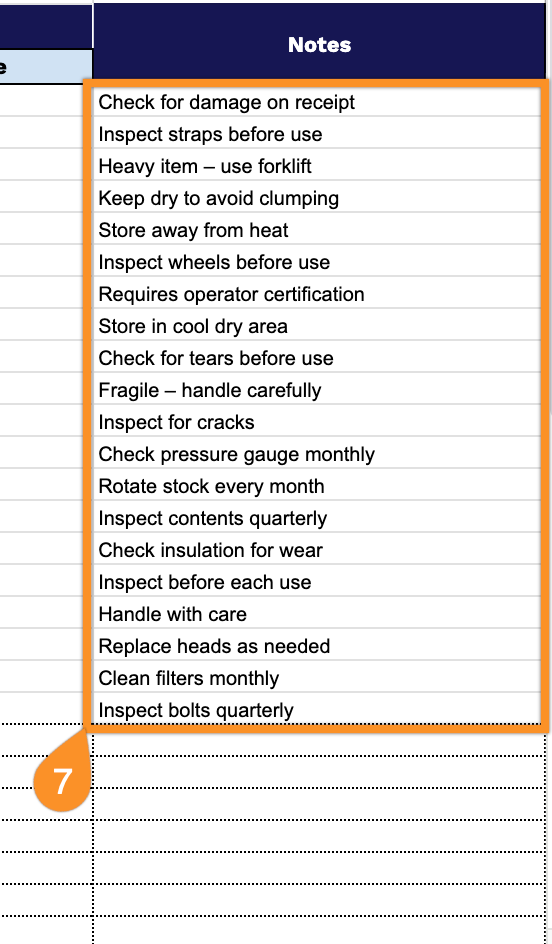

7. Any remaining relevant details should go in the Notes section.