Keeping track of lab inventory can be a real challenge. Between chemicals, equipment, consumables, and specimens, it’s easy to lose sight of what you have, where it’s stored, and when supplies are running low.

For research laboratories, clinical facilities, and educational science departments, disorganized inventory often leads to unnecessary costs, workflow disruptions, and last-minute scrambles to reorder critical supplies.

Our free lab inventory spreadsheet template provides a straightforward way to organize your supplies. It works with Google Sheets and Excel, and is available as a PDF, so you can use the format that suits your workflow best.

Quick Jump

ToggleWhat Is a Lab Inventory Spreadsheet?

A lab inventory spreadsheet is a digital document used to track and manage laboratory supplies, equipment, chemicals, and other materials.

This tool helps lab managers maintain adequate stock levels, prevent shortages or overstocking, ensure safety compliance, and streamline the procurement process.

Download Spreadsheet Daddy’s Free Lab Inventory Management Spreadsheet

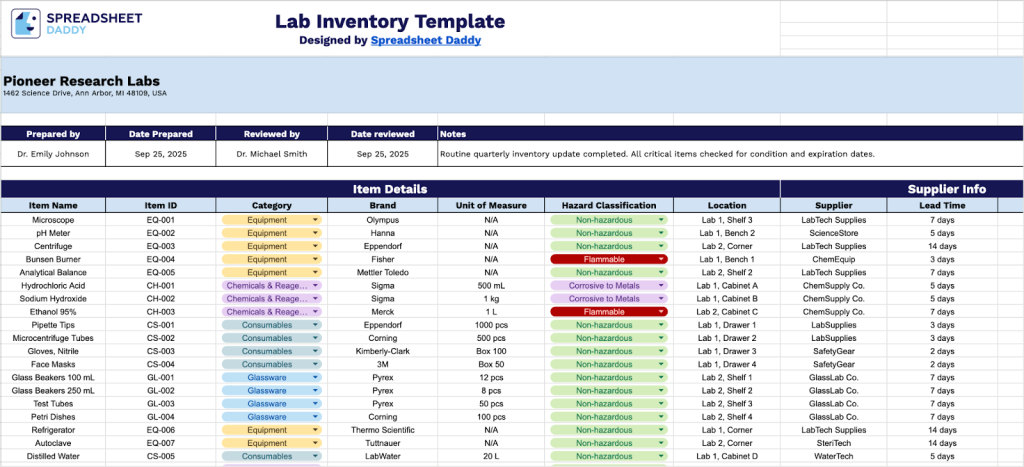

Our detailed Lab Inventory Template allows you to manage laboratory supplies, equipment, and materials with organized fields.

Customize the template by adding or removing columns to match your workflow, whether you’re running a university research lab, hospital facility, quality control department, or any other operation that handles laboratory materials.

What’s included

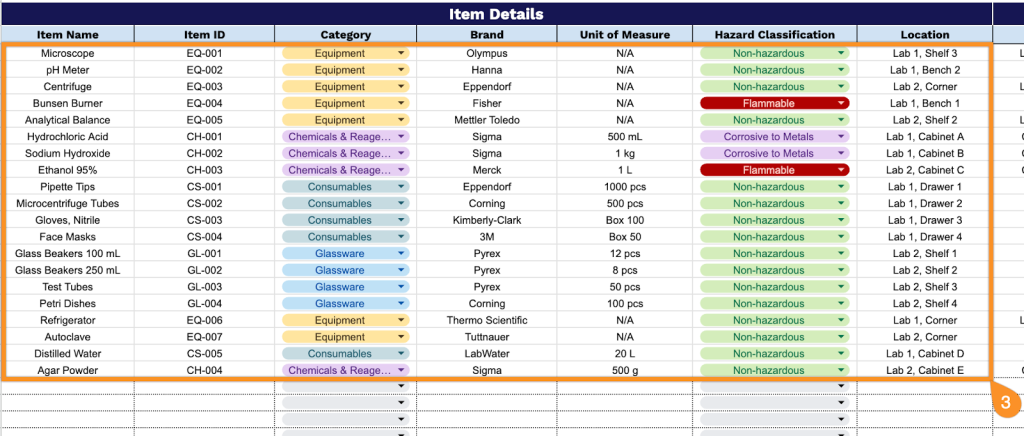

- Comprehensive item tracking system: Manage all laboratory materials with dedicated columns for Item Name, Item ID, Category, Brand, Unit of Measure, Hazard Classification, and Location. This structured approach ensures precise identification, categorization, and safe storage of chemicals, equipment, and supplies throughout your facility.

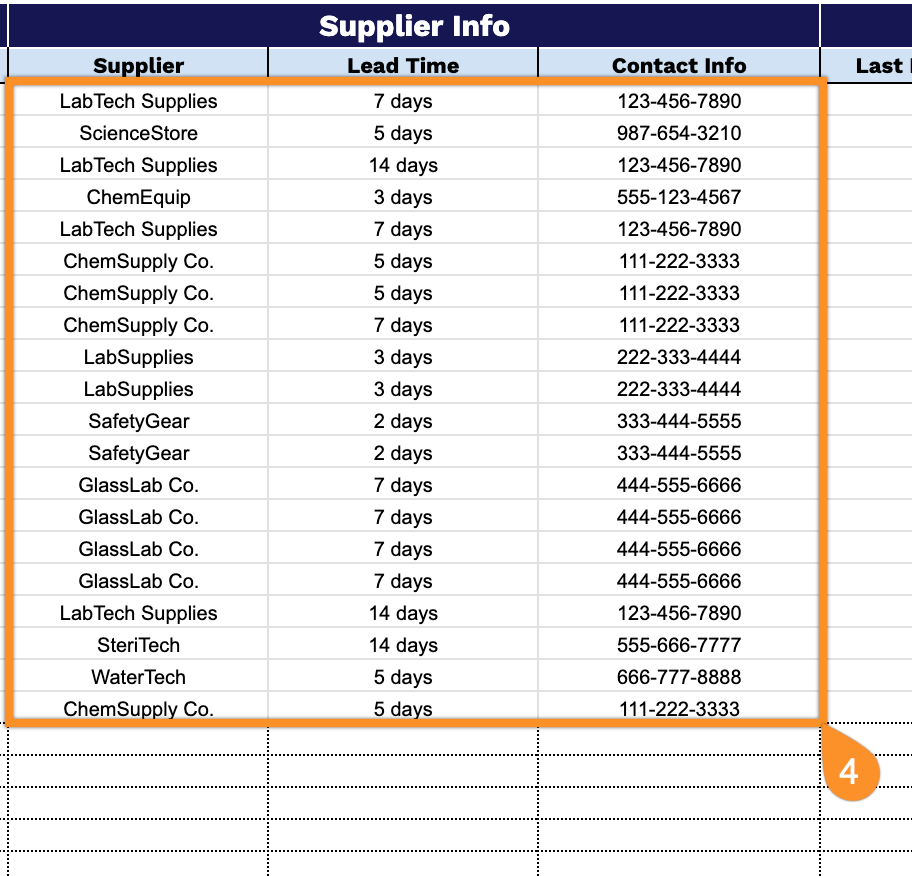

- Supplier management and procurement data: Track vendor relationships with columns for Supplier information, Lead Time, Contact Info, Unit Cost, and Purchase Date. This streamlines reordering processes, helps you manage budgets effectively, and maintains reliable communication with your suppliers.

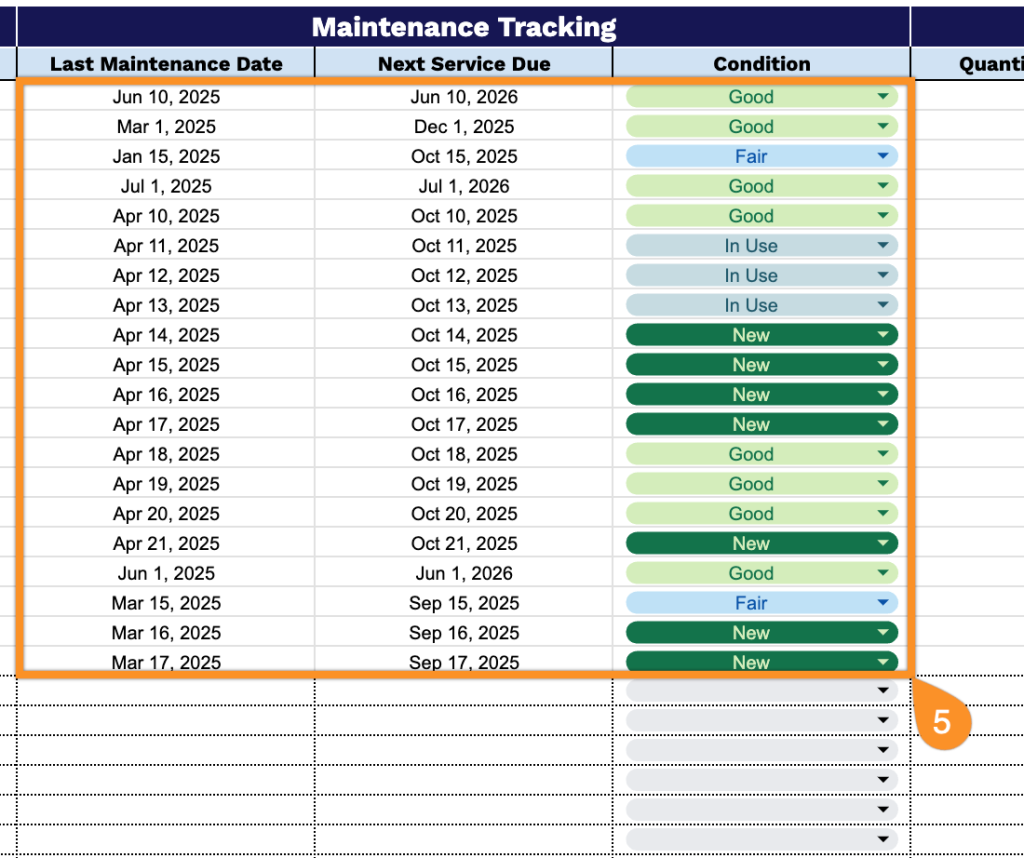

- Maintenance and service scheduling: Monitor equipment health with Last Maintenance Date, Next Service Due, and Condition status fields, which help you keep laboratory equipment calibrated, functional, and compliant with safety standards while preventing unexpected breakdowns.

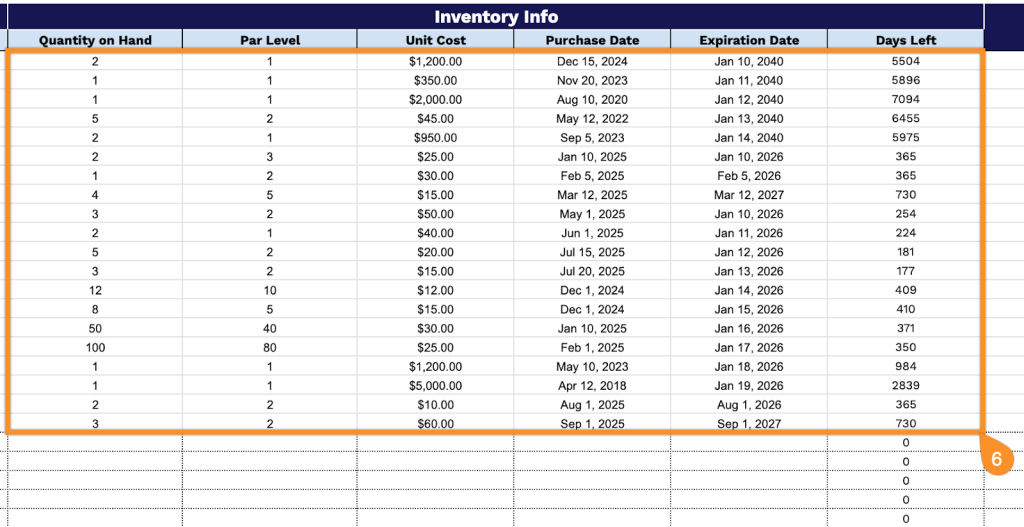

- Intelligent inventory control with par levels: Maintain optimal stock levels using Quantity on Hand and Par Level threshold columns. The system shows you when items fall below minimum requirements, so you can avoid supply shortages that might disrupt necessary research or testing work.

- Expiration and safety monitoring: Manage material safety with Expiration Date tracking, calculated Days Left, and Hazard Classification fields. This integrated system supports proper chemical rotation, helps you stay compliant with safety regulations, and reduces waste from expired reagents and supplies.

How to Use Our Lab Inventory Spreadsheet Template

1. Start managing your lab inventory by making a copy in Google Sheets or downloading it in Excel or PDF format.

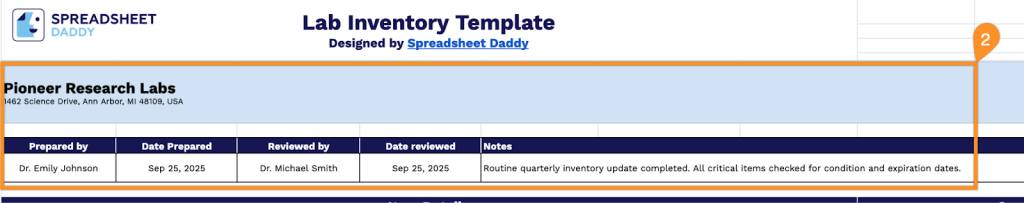

2. Record your company name, street location, stock coordinator data, and completion date. Enter the manager’s name and the date of the inspection, and use the Notes section to capture any additional details.

3. Complete the Item Details section by entering all essential laboratory material information:

- Item Name: Specify the complete product name and technical description of the laboratory item.

- Item ID: Enter the unique identifier, catalog number, or SKU assigned to each item for inventory tracking.

- Category: Select the appropriate classification (Chemicals & Reagents, Consumables, Glassware, Plasticware, etc.).

- Brand: Include the manufacturer or supplier brand associated with the item.

- Unit of Measure: Record the standard unit of measurement for inventory tracking (e.g., liters, grams, pieces, boxes).

- Hazard Classification: Document material classification, like Flammable, Explosive, Oxidizer, Non-hazardous, etc.

- Location: Specify the storage location within the laboratory (cabinet number, shelf, room designation, etc.).

4. Document supplier relationships in the Supplier Info section for vendor management:

- Supplier: Enter the name of the vendor or manufacturer providing the laboratory materials.

- Lead Time: Record the expected delivery timeframe from order placement to receipt of materials.

- Contact Info: Include phone numbers, email addresses, and key contact persons for ordering and technical support.

5. Track equipment maintenance in the Maintenance Tracking section for compliance and operational efficiency:

- Last Maintenance Date: Document when the most recent service, calibration, or inspection was performed.

- Next Service Due: Record the scheduled date for upcoming maintenance or calibration requirements.

- Condition: Note the current operational status and any performance issues requiring attention (e.g., New, Good, In Use, Needs Repair, etc.).

6. Monitor stock levels and financial data in the Inventory Info section for laboratory management:

- Quantity on Hand: Document the current number of units available in the laboratory.

- Par Level: Set the minimum stock threshold that triggers reordering to prevent shortages.

- Unit Cost: Enter the purchase price per unit for budget tracking and cost analysis.

- Purchase Date: Record when the item was acquired for warranty and aging tracking purposes.

- Expiration Date: Document the expiration or stability date for time-sensitive materials and reagents to ensure proper storage and use.

- Days Left: The template automatically calculates the remaining shelf life to prioritize usage and prevent waste of expired materials.

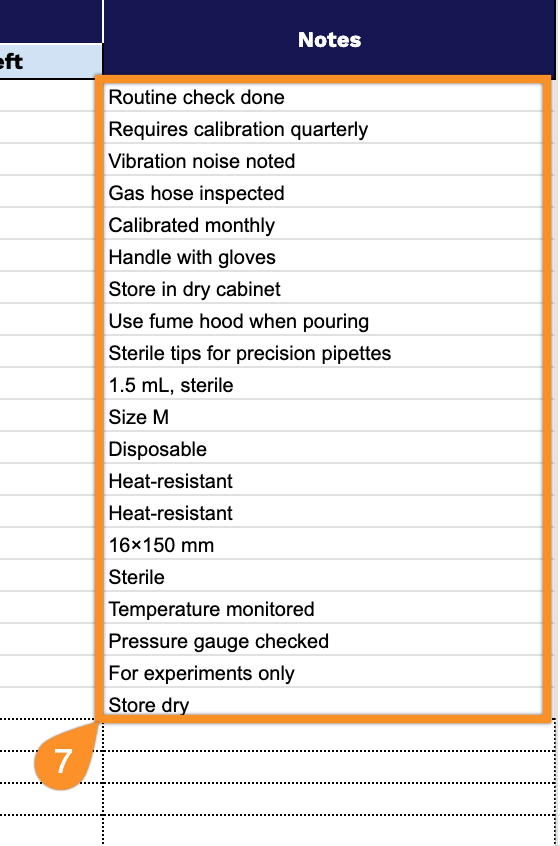

7. Use the Notes section for documenting any other details that apply to an item.